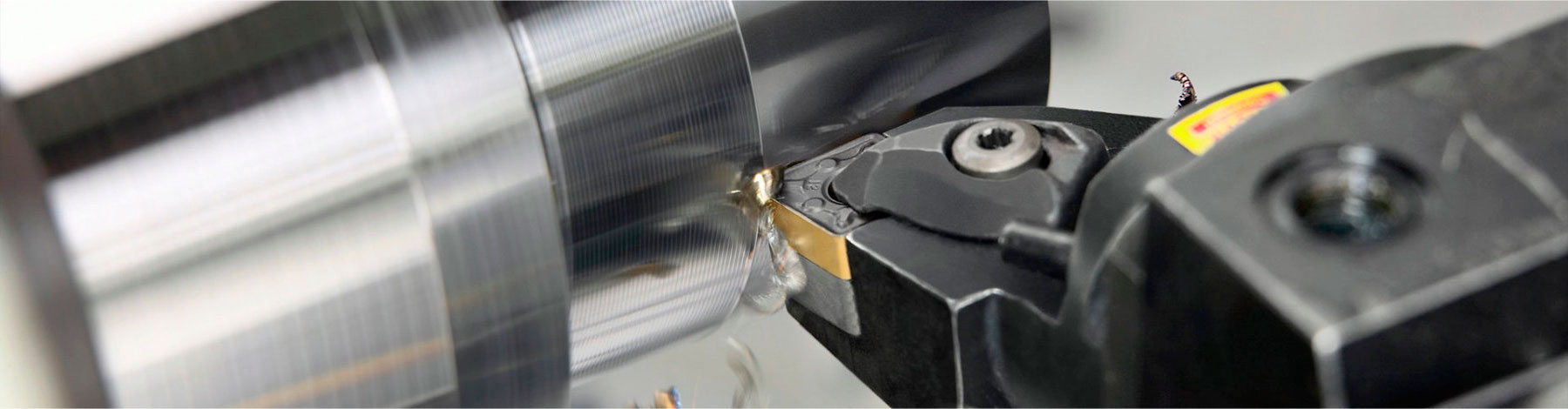

Turning on CNC machines

Turning on CNC machines is the processing of metal products by turning and boring external and internal objects during the rotation of the product, of almost any shape, cylinder and cone inclusive. The main types of production steps in the processing of products during turning operations are chamfering, cutting, cross-cutting, internal and external threading, and grooving.

Research and Development enterprise “Centr Tochnoi Mechaniki” – OOO NPP “CTM” offers to perform turning on CNC machines. Turning is performed by highly technically trained professional engineers on high-precision Japanese equipment, subject to modern technical requirements for processing. CNC machining quality is perfect. Turning products are used in all industrial areas without exception.

Products made with the help of turning technologies are used in many devices, machines, equipment, units and their components. Therefore, turning is so popular and high demand.

High production and processing speed, the ability to produce stock-produced and piece goods of impeccable quality, are the main competitive advantages of the “Centr Tochnoi Mechaniki” company. The ability of developing a technological process and a control program for CNC machines allows NPP “CTM” to make the process of turning products on CNC machines maximally effective.

Sizes (dimensions) of workpieces

Maximum diameter-400mm Length-1000mm

Processable materials

- Non-ferrous alloys

- Stainless steel

- Titanium alloys

- Refractory and high temperature resistant alloys

- Polymers

Types of manufactured products

- Custom complex designs

- Special fasteners;

- Bushings, studs, rods, axles;

- Fittings, tees, adapters, caps, plugs;

- Core members, cages, frames;

- Body rotation frames, shafts.

Degree of accuracy

Maximum accuracy – 6 accuracy degree

Production capacity

OOO NPP “CTM” performs turning on OKUMA and MAZAK multifunctional machining centers which are recognized brands in the area of high-tech processing. The use of this equipment by itself is a guarantee of high quality finished goods. The degree of processing and the complexity level allows to work with hard in processing and complex materials, to perform ultra-precise and ultra-fine finishes. Innovative numerical control capabilities allows to perform super complex cuttings with micron accuracy.

The Research and Development enterprise “Centr Tochnoi Mechaniki” takes orders for turning on CNC machines of any complexity and invites large enterprises, small and medium businesses to cooperate.