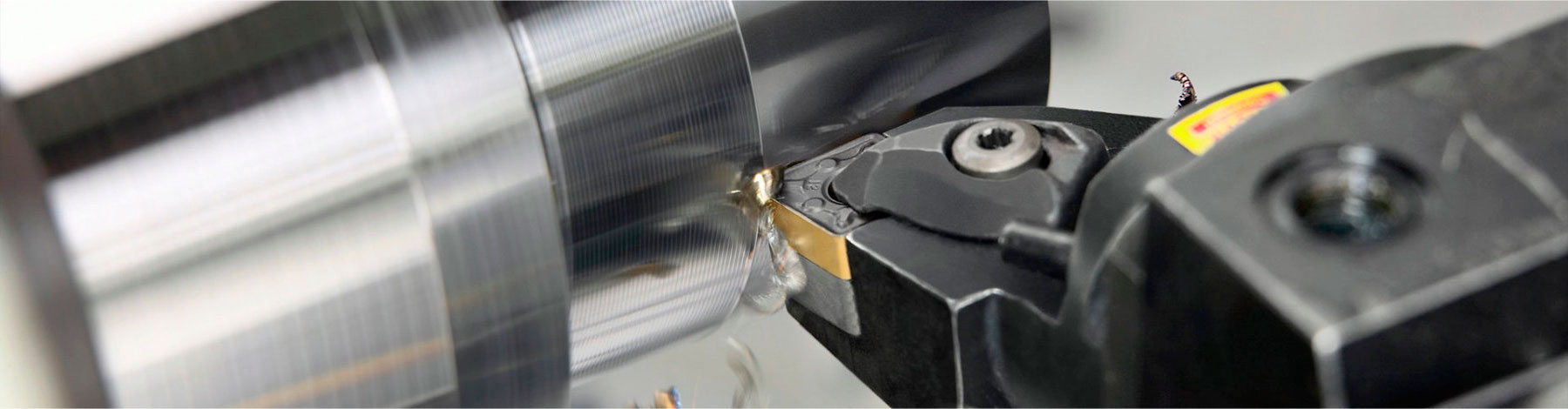

Milling on CNC machines

Milling operations on CNC machines are performed by the Research and Development enterprise “Centr Tochnoi Mechaniki”. Milling on CNC machines is performed on high-precision Japanese equipment by highly technically trained professional engineers , subject to modern technical requirements for processing. Milling of products on CNC machines, is performed by cutting materials using cutters, special nozzles for different outline, slope, diameter and depth of cut. Intermediate and finishing surface processing is performed through the use of cutters. There are face, form and slab milling surface treatment. Odd-shaped parts are produced with this type of processing.

Particularities of milling on CNC machines

Milling on CNC machines completely eliminates the human factor in the processing. Errors and inaccuracies are ruled out, automatic software control can never make a mistake. Product quality is impeccable and consistent. Work is performed quickly and efficiently. The cutter changes automatically in accordance with the process and control program, if it is necessary. Milling of products of high complexity is possible. Performing of such work is possible because of modern high-tech equipment that is used by “Centr Tochnoi Mechaniki”. Parts produced by such equipment are of the highest quality in terms of the mill finish and accuracy.

Types of milling

Production of base parts milling of, welding and assembly goods, milling of thread and helical surfaces, milling of tooth gear, pinion gear, shafts, splined shafts and bushings, keyway and other types of slots, flat surfaces.

Sizes (dimensions) of workpieces

Maximum dimensions 1000*600*400mm

Processable materials

- Non-ferrous alloys

- Stainless steel

- Titanium alloys

- Refractory and high temperature resistant alloys

- Polymers

Degree of accuracy

- Hole accuracy – 6 accuracy degree

- Linear accuracy – 6 accuracy degree

- Coordinate dimensions accuracy ± 0,001mm

OOO NPP “CTM” performs metal processing on multifunctional machining centers OKUMA and MAZAK which are recognized brands in the area of high-tech processing. The use of this equipment by itself is a guarantee of high quality finished goods. The degree of processing and the complexity level allows to work with hard in processing and complex materials, to perform ultra-precise and ultra-fine finishes. Innovative numerical control capabilities allows to perform super complex cuttings with micron accuracy.

High production and processing speed, the ability to produce stock-produced and piece goods of impeccable quality, are the main competitive advantages of the “Centr Tochnoi Mechaniki” company.

The possibility of developing a technological process and control program for CNC machines allows NPP “CTM” to put non-standard, unique parts into production.

The Research and Development enterprise “Centr Tochnoi Mechaniki” performs milling on CNC machines with high accuracy, as well as other types of high-precision metal processing, to order. Large enterprises, small and medium businesses are invited to cooperate.